Climate ambition at Hiab

- Hiab Corporate

- About Us

- Sustainability

As a business, we strive to be a customer-focused global leader in sustainable material flow. Hiab has a breakthrough objective to reduce CO2 emissions by 200,000 tonnes by 2024 which has been set in line with the Cargotec climate ambition to be a 1.5 degree company.

To reduce the climate impact of our own operations, we are increasing the share of renewable energy in our operations with the target to be climate neutral.

Here we strive to:

- Reduce value chain emissions by at least 50%.

- Be at the forefront of decarbonisation in our core markets and industries by:

- Engaging suppliers to reduce emissions from sourcing.

- Reducing the carbon footprint in the product use phase

- Reducing the environmental impact of our products and, at the same time, make them more cost-efficient and productive.

- Capture and create opportunities around the circular economy. - Expand our electric offer using the most eco-friendly materials.

Learn more about the Cargotec climate ambition here

Vlot Logistics and Hiab Leads the way to Zero Emission

Hiab customer Vlot Logistics in the Netherlands shares the benefits of using their electric HIAB loader cranes and electric

CTA Button

mounted

forklift.

Future-ready for tomorrow's trucks

The load handling industry is changing – fast. Operating restrictions in cities, changes to environmental legislations and a demanding fuel economy are driving challenges for more sustainable business. Tomorrow’s trucks will need to give you the same productivity or more with less environmental impact. And your fleet will need to be ready.

Hiab is here to help. We are at the forefront of developing more sustainable load handling solutions, and we can already offer a range of innovations designed to support your business future today. No matter if your fleet will be powered by electric motors or alternative power sources, our equipment can be used with tomorrow’s trucks. So, you can be confident that our solutions will enable more sustainable and more profitable possibilities for your operation and help build a better tomorrow.

Below you will find a range of smart and sustainable Hiab innovations designed to support the future of your business.

Download the Hiab Sustainable Solutions brochure

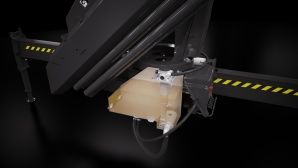

MOFFETT eSeries NX

The MOFFETT eSeries NX has been developed based on the world’s first all-electric truck mounted forklift, a revolutionary turn in forklift logistics. All MOFFETT eSeries NX feature all wheel drive, 4-way steering, high-tech dash display, real-time operational insights and multiple charging options.

Hiab HiConnect

Hiab HiConnect™ telematics system keeps you one step ahead with next-generation intelligence today. By enabling new insights, it helps you to identifiy major savings in carbon emissions and fuel wastage with unnecessary idling.

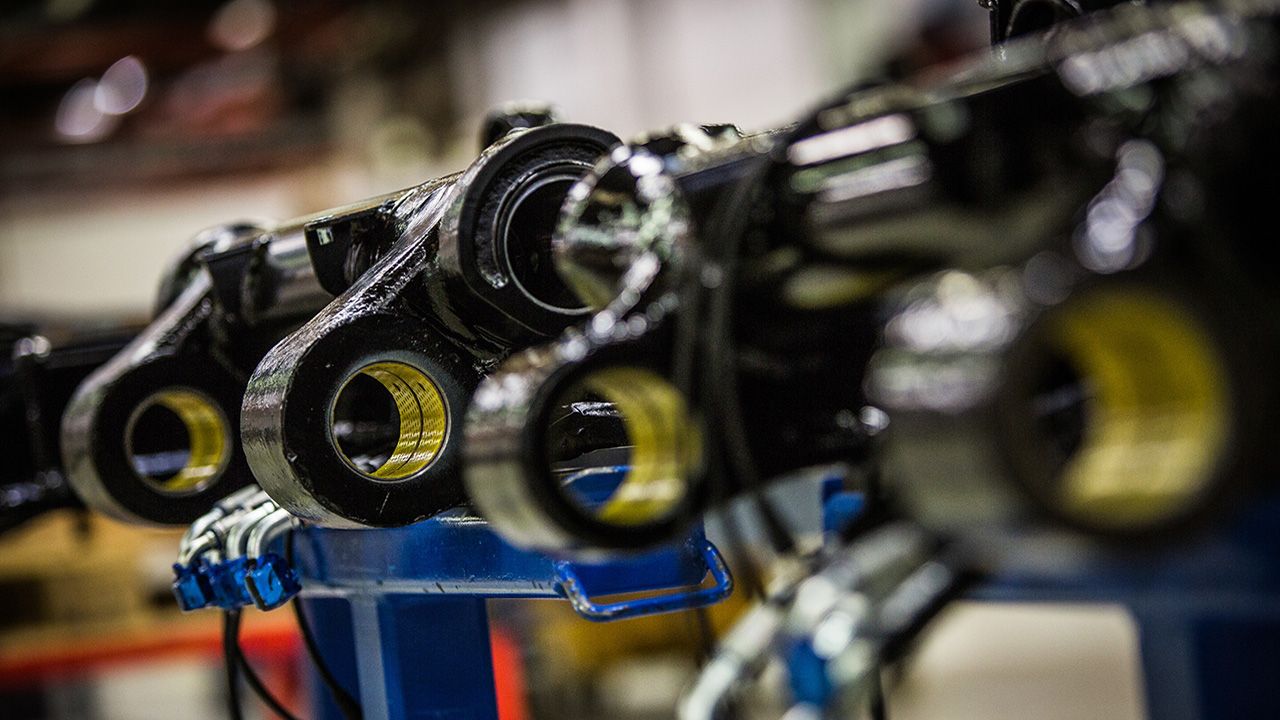

ePTO

Arbeta i tystnad, helt utan utsläpp

ePTO står för Electric Power Take Off, en elhydraulisk kraftkälla för kranar. Den är monterad parallellt med det traditionella motordrivna systemet, vilket gör att operatören kan arbeta med lastbilsmotorn avstängd och ändå utföra samma jobb som vanligt. ePTO innebär flera fördelar, både miljömässigt och ekonomiskt. Till exempel 60–70 % lägre energiförbrukning, 70 % lägre driftskostnader och 30 % lägre ljudnivå.

eRoller Crane

Den nya, tysta kranen

Kranfotens eldrivna enhet gör att kranen tyst kan förflytta sig längs lastytan, vilket gör att kranen hamnar närmare där den behövs för lastning och lyft. Möjligheten att arbeta inom stadens bullergränser och utsläppsfri drift gör denna kran till en miljövänlig produkt och öppnar dörren för jobb där traditionella lösningar inte är möjliga.

CYCLONE-tanken: TÄNK PÅ MILJÖN SAMTIDIGT DU SPARAR PENGAR

Minska dina driftskostnader

Det effektiva CYCLONE-tanksystemet behöver inte lika mycket olja och det innebär att du sparar på oljekostnaderna under kranens hela livslängd.

Väldigt enkelt, men en bra besparing för ditt företag.

Plats för mer nyttolast

Eftersom CYCLONE-tanken, tack vare den höga prestandan, kräver mindre utrymme blir det mer ledig plats på lastbilen och det lägre oljebehovet gör att mer vikt kan användas för nyttolast.

Ditt företag ska satsa på det som verkligen betyder något.

MULTILIFT + electricity = the future of urban load handling

Installed on an electric truck chassis, MULTILIFT’s quiet and emissions-free electric hooklift is an environmentally friendly solution for urban use.

- Zero exhaust fumes for improved quality of life.

- Ideal for discreet late-night and early-morning transport of containers.

- Combined with the Performance Package the hooklift uses less energy, ultimately saving battery power and further helping the electric truck to maintain its range.

Savings on all sides with MULTILIFT features

Innovative features for your MULTILIFT can increase your payload opportunities while simultaneously reducing your environmental impact.

- PerformanceOptions™ reduce your fuel consumption and emissions.

- Fast Performance™ and Sequence Performance™ save time and effort to boost productivity.

- Lighter and stronger steel structure increases payload while further reducing fuel consumption.

- Quiet Performance™ reduces noise pollution to surrounding environments.

Performance for a sustainable future: MULTILIFT hooklifts made from fossil-free steel

Hiab has partnered with the global steel company SSAB to pioneer the use of fossil-free steel with zero CO2 emissions in the load handling industry. The first product is a MULTILIFT Ultima hooklift that was unveiled at the IAA Transportation 2022 in Hannover, making it the first hooklift of its kind in the world.

Steel production accounts for 7% of the global CO2 emissions and steel components are Hiab’s main contributor for CO2 footprint when producing load handling equipment. From 2026, Hiab will start to deliver load handling equipment made from fossil-free steel, just as strong and long-lasting, but with zero CO2 emissions. By 2030, Hiab aims to make its own operations carbon-neutral providing true performance for the next generation.

Stay charged and reduce emissions

The tail lift Solar Charger solution generates power through solar panels on the roof of your truck or trailer and stores it in your tail lift battery, ensuring your tail lift is always charged and ready to go.

- Clean, cost-effective and infinitely renewable

- Charging continues even when the vehicle is stationary

- Fast return on investment

@2025 Hiab Corporation